Plastics technology, toolmaking and test equipment construction Your partner for plastics technology with longstanding experience and state-of-the-art manufacturing expertise

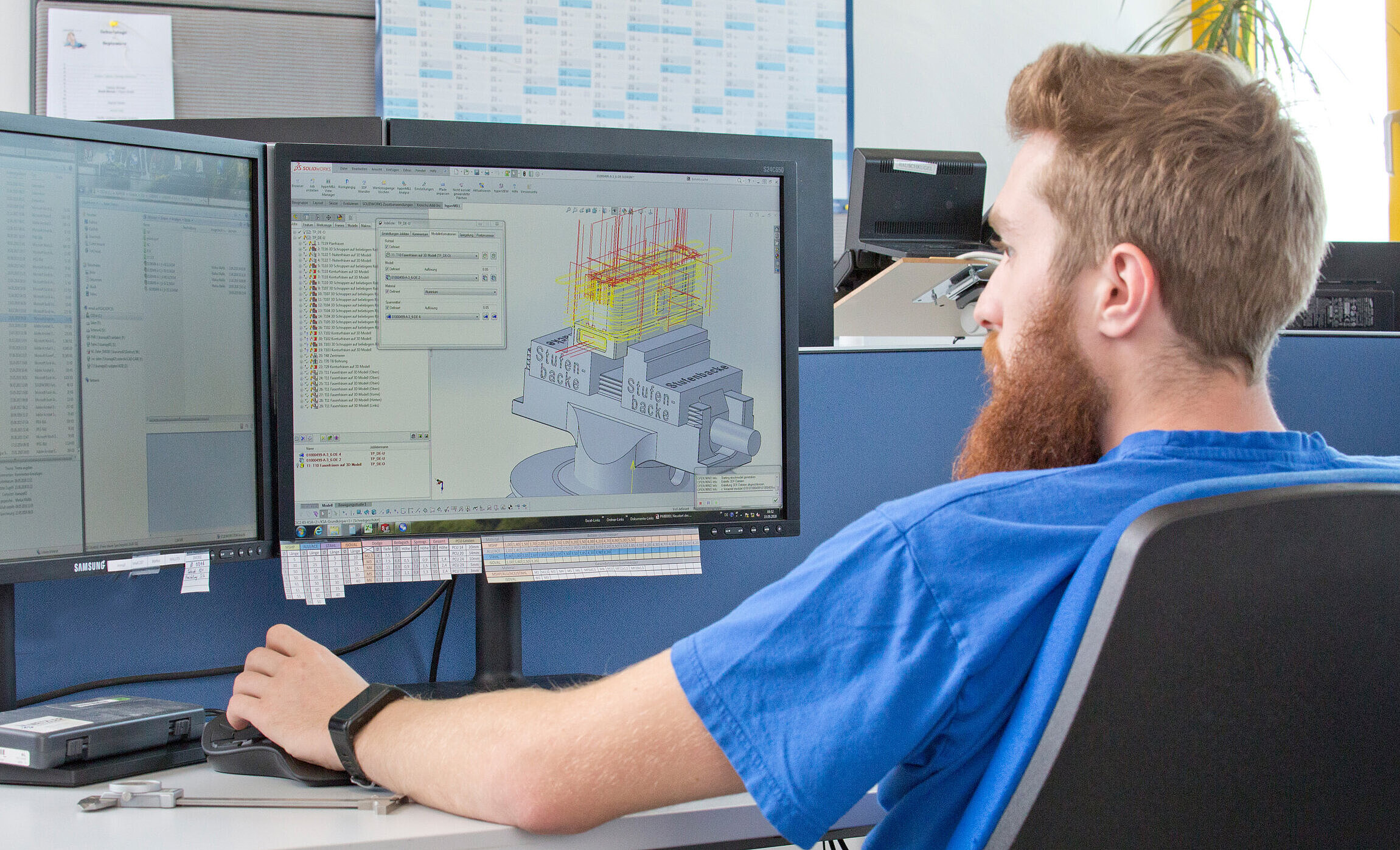

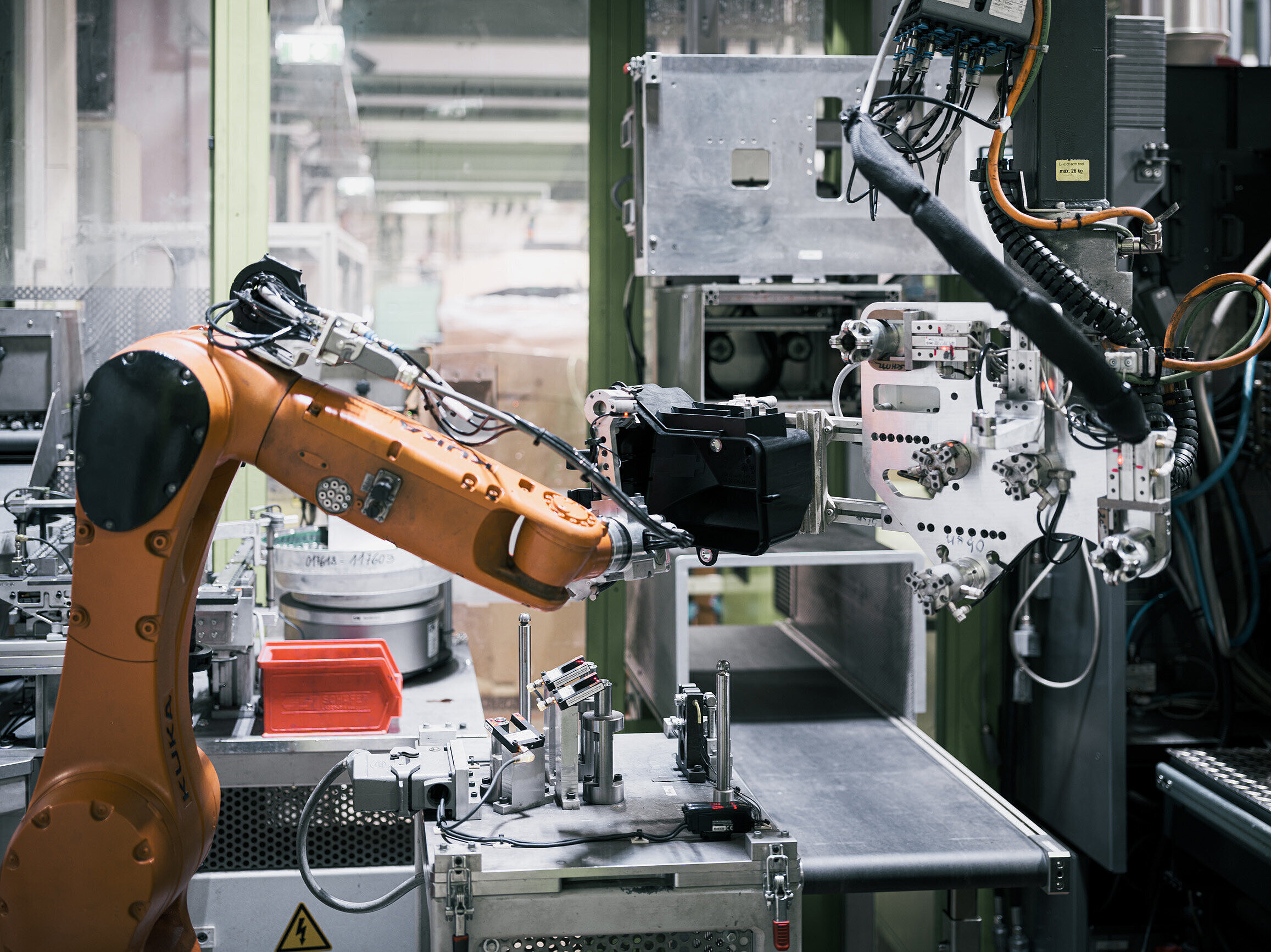

Drawing on decades of development experience, we deliver end-to end services – from the brainchild to the series part – from a single source. Our in-house Toolmaking Department and state-of-the-art production facilities ensure smooth workflows and impeccable quality.

All components are tested professionally and efficiently in our in-house test laboratory. This process guarantees that every single part meets the most rigorous requirements. Our portfolio of services includes the development and production of plastic parts, power distribution boxes and elastomer parts – all customised to your needs.